Technology

ATOS (Advanced Topometric Sensor) - 3D Digitizer

A stand-alone system that mainly consists

of a sensor comprising two cameras, projector and stand, the control unit

for the sensor head and a high-performance Linux PC. Objects can

be measured quickly and with high local resolution. Measurements

are automatically transformed into a common global coordinate system.

Measuring data are made available as point clouds, sections or STL* data.

This allows accurate measurement of the shape and size of the visible

surface of almost any 3D object. The ATOS system allows for an efficient

and precise data gathering and reporting in:

*STL - A internationally recognized standard file format used in reverse

engineering for rapid prototyping that stores xyz coordinate measurements.

TRITOP - 3D Coordinate Measuring Machine (CMM)

An industrial, non-contact optical measuring

system for exact 3D coordinate acquisition of discrete object points.

This mobile technology supports time-optimized measurements for on-site

quality control and deformation analysis. The TRITOP system is mainly

used to take high resolution two-dimensional pictures of objects to provide

accurate large scale 3D coordinate frameworks utilizing photogrammetry

techniques. It is designed to define exact 3D positions of markers and

visible features and offers time effective on-site measuring and is an

add-on to ATOS.

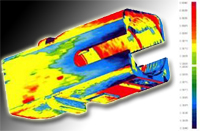

CGI®

CSS 1000 System - First Article Inspection

A first article inspection system

that offers superior digitizing capability and performance over laser

digitizers, touch-probes, X-rays and in-house CAD reproductions for

parts with internal features. The system significantly reduces costs

and processing time involved with inspecting first article parts with

complex internal geometry. This system simultaneously digitizes

both the surface and the internal geometry of a part.

- The system is designed to reverse engineer parts that can fit within an envelope of 12 x 10.5 x 8 (over 1000 cubic inches) or 30 x 26 x 20 cm (over 15600 cubic centimeters).

- The advanced system design increases productivity by allowing multiple parts of the same material to be processed simultaneously.

- Aluminum alloys, plastics, steel, cast iron, brass, stainless steel, copper and wood can be processed on the system. If your part is machinable, the CSS 1000 system can capture its geometry.

- Layer thicknesses range from 0.0005 to 0.010 inches

The CSS 1000 can output the following formats:

- IGES, STL, SDRC, ISO G-Code, ASCII, DXF, IBL and VDA