Applications

Allowing our clients to leverage the latest 3D scanning technology from

our services, we are able to help them enter the 3D digital world without

the expense of having to invest into the technology itself. By

providing accurate 3D digital data to our clients, they will be able

to view and modify the data as they please. This will help them

save on cost and time from modifying the actual part, model or object.

Analysis

Perform complete accurate analysis on actual parts – digitally. Assess

true performance characteristics to compare with CAD model-based analysis.

Custom Manufacturing

Enable mass customization. Rapidly prototype and manufacture unique

individualized products as a competitive advantage over mass production.

Digital Archiving

Record physical characteristics of designs or natural objects for archival

purposes when CAD files do not exist, or accurate 3D representation

is required.

Industrial Design

Incorporate unique shapes into design and engineering of new industrial

and consumer products from natural or hand-sculpted forms.

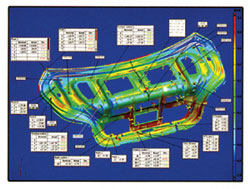

Quality Inspection

Compare accurate digital models with CAD to ensure products meet intended

design and performance characteristics within specified tolerances.

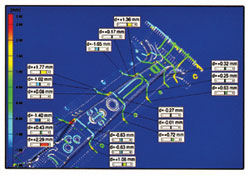

Reverse Engineering

Create accurate digital models of existing components, re-design and

re-engineer parts. Hand-worked changes for CAD can be captured.

Visualization

Digitally express complex 3D models of physical objects. Enable collaboration

and sharing of 3D descriptions of physical objects for better decision

making.

Additional

Applications:

Additional

Applications:

- 1st Article Inspection

- Blow & Injection Molding

- CAD Comparison

- Digital Mock-Up

- Dies & Molds Confirmation

- Rapid Manufacturing

- Sheet Metal Analysis

- and much more!